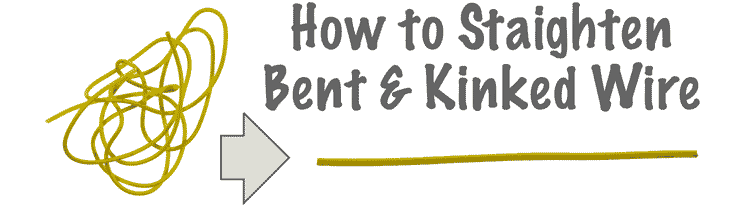

How to Straighten Insulated Copper Wire

A simple practical, very quick and easy method for straightening electronics project connecting wire or hook-up wire from the spares box so it can be re-used again.

Home » Construction & manufacture » this page

Construction Hints & Tips Includes:

Practical hints & tips overview

How to make twisted pair wire

How to drill cases that are painted

How to use heat shrink sleeving

How to tidy wiring with looms

How to straighten kinked connecting wire

Bending & forming axial component leads

Connecting wire used for electronics projects can be expensive and as a result it is often saved from one project to the next. Knowing how to straighten this wire can be invaluable.

Unfortunately this insulated copper wire can receive many kinks and bends when it is stored. To re-use the copper wire satisfactorily it is necessary to know how to straighten the wire and to remove the kinks and bends.

It is not easy to remove these kinks and bends from the insulated copper wire without knowing how to do it.

It is well worth saving connecting wire as it can be expensive to buy, and also when just a short length of insulated copper wire is needed, it can time consuming to buy each time, and keeping a stock of all the wire that might be needed can be too expensive for the average constructor.

Removing the kinks and bends from the copper wire

The most obvious way to try to remove kinks and bends from a wire is to try to put a reverse bend into it. This is not only very time consuming, but it is also not at all effective. The kinks and bends cannot be fully removed this way and the wire still looks very used and untidy.

Video: How to straighten hook-up wire with bends and kinks

It is possible to buy a wire straightener or cable straightener, but is this really necessary if there is a no-cost way of doing it.

The simplest way of quickly removing these bends is to use the shaft of a screwdriver as shown below.

When selecting a screwdriver for this, it is probably best to select one that has a good round shaft - often a reasonably large one. If it is too small, then it won't be as easy to use.

Wrap the wire once round the shaft and then pull the wire so that the wire is pulled over and around the shaft.

Sometimes, if the kinks and bends in the wire are not too bad, then it can be sufficient to pull the wire over the screwdriver shaft or other suitable surface, and not completely wrap the wire around it.

When doing this, it may be necessary to just hold the wire gently in position. This can often be done with a thumb.

It is often sufficient to pull it over the screwdriver shaft just once, but if not then do it a second time.

Although very simple, this method of removing those unwanted bends from copper wire is a particularly effective method of enabling old connecting or hook-up copper wire from the junk box to be re-used for making connections in projects.

It also saves the cost of buying a wire straightener, which may be costly, and again it will introduce another delay as it is bought.

Using this manual method of straightening connecting wire or hook-up wire can provide a considerable cost saving, in terms of not having to buy new wire all the time, and not having to buy a wire straightener.

It also enables projects to move ahead rather than having to wait for new wire to be purchased, or having to re-use old wire as it is with all its bends and kinks. This ensures that the appearance of a project looks good, while not spending a fortune on buying everything new, or having to wait for it any new wire to be bought and collected or delivered.

More Construction Ideas & Concepts:

Soldering

SMT component soldering

ESD - Electro-Static Discharge

PCB manufacture

PCB assembly

Return to Constructional Techniques menu . . .