Resistor Specifications: Specs & Parameters

There are several resistor specifications or specs and parameters that need to be considered when choosing a resistor for any circuit design, repair, or aspect of an electronic circuit design.

Resistor Tutorial Includes:

Resistors overview

Carbon composition

Carbon film

Metal oxide film

Metal film

Wirewound

SMD resistor

MELF resistor

Variable resistors

Light dependent resistor

Thermistor

Varistor

Resistor colour codes

SMD resistor markings & codes

Resistor specifications

Where & how to buy resistors

Standard resistor values & E series

Resistors are a very important type of electronic component in any circuit design. As a result, billions of resistors of all types are used each year.

Selecting the right resistor is key to ensure that the resistor is right for the circuit design, and understanding the resistor specifications is important to ensure that nothing is overlooked.

Although the primary resistor specification is its resistance, there are many other specifications that are also very important. Ignoring them could mean that the particular resistor selected may not be suitable for the circuit design and this might result in it not working.

There are many types of resistor and many resistor specifications - having a good knowledge and understanding of these is essential for anyone involved in electronics design, repair, service, test, or any aspect of electronics.

Whether the resistor is to be used within a low power circuit to set the bias, as a laod resistor, a ballast resistor, or whatever, understanding the requirements and specifications for the different types of resistor is very important.

Resistance specification

The resistance is obviously the key specification for these electronic components. The value of the resistance is required by the calculations for the particular application and particular position int he electronic circuit design where it is to be used.

It is always best to use preferred values as these are easier to obtain. There are several series of resistor values that are used. These are referred to as the E-series. E3 has three values in a decade, i.e. 1.0, 2.2 and 4.7. Values of 10Ω 22Ω 47Ω are available in the tens of Ohms decade, 100Ω 202Ω 470Ω are available in the hundreds of Ohms decade and so forth.

It is always preferable to use as few values in a circuit design as possible as this reduces the number of different types required for any one design. Other series are also available, E6 with six values in each decade: 1.0, 1.5, 2.2, 3.3, 4.7, 6.8. There are also E12, E24, E48 and E96 etc values available, although their costs can increase marginally and they mean that many more component types are needed in a given design.

Resistance tolerance specification

Another important aspect of the resistor specification set is the tolerance. Virtually all resistors that have markings on their packages have this within the code or alongside the value.

The tolerance of a resistor, or for that matter any electronic component, is the deviation of its value from the nominal value stated. Normally this is measured at 25°C, but if other temperatures were to be used, then this would be mentioned in the specification.

The tolerance is normally expressed as a percentage (±%) of the nominal value.

Tolerance values of ± 20%, 10%, 5%, 2% and 1% are common. The old carbon composition resistors typically had values of ±20% for most resistors and tighter tolerance ones were ±10% or occasionally 5%.

Modern metal oxide film or metal film are typically ±2% or ±1% and some tighter tolerances are available.

For really precision resistors, wirewound varieties are used. Although some wirewound resistors are used as power resistors, others are designed specifically for use as precision resistors and exceedingly tight tolerances can be obtained. Some may be as tight as ±0.005%. These can be used within measuring instruments, and other similar applications.

Resistor accuracy specification

The accuracy is not the same as the tolerance. Instead the resistor accuracy is the resolution or number of digits to which the resistance is specified.

For traditional low accuracy resistors, three rings are sufficient to give the value, but high accuracy ones need further rings for the coding of the more accurate value.

High accuracies also go hand-in-hand with closer tolerances, but the two specifications are actually different.

Long term stability

The long term stability specification for a resistor is defined as the resistance variation over a over a period of time when measured at a referenced temperature and subjected to a variety of operating and environmental conditions.

The long term stability specification of a resistor is normally expressed as the percentage from the absolute value of the resistor value at time = 0.

.Although the stability of a resistor can be difficult to specify and measure because it is tends to be application and situation dependent, it is nevertheless important for some circuit designs.

The very old carbon composition resistors were known to be very poor with values changing by very significant percentages over time - vintage radio restorers will testify to this, seeing some vary by 100% and more. However modern resistors are very much better, As a general rule, resistors using bulk metal and wirewound designs are most stable, while those electronic components using composition materials are less stable.

To gain the best resistance stability, it is essential to run critical resistors well within their power limits, with limited temperature rise. Excess temperature is one of the main issues causing poor stability, so keeping the resistor temperature changes as small as possible helps.

Resistor type

Although the actual type of resistor may not be considered to be a specific resistor specification, it is nevertheless an essential element in judging the performance of the resistor. Different types of resistor will have different performance parameters. Some will have low levels of inductance, others will have higher resistance tolerance / accuracy specifications, others may be able to dissipate higher power levels, etc.

There are many types of resistor, each with their own advantages and disadvantages and this will impact on their specifications:

Carbon composition: Carbon composition resistors are are not widely used these days. They are used in some areas though:

Vintage radio repair: These resistors are used for vintage radio repair. As this type of resistor would have been used in most of the electronic designs for vintage radios and antique radios, replacing them with the same type will mean that their specifications are as similar as possible and the circuits will perform in the same way.

Transient absorption: One of the key attributes and specifications of carbon composition resistors is that they can absorb transient spikes without undue damage. Other types of resistor may be damaged if they need to absorb a large transient because their size and thermal mass may not enable them to withstand the short pulse of energy. Because of their size, construction and overall capability, carbon composition resistors are able to withstand transients quite easily. It is this attribute of specification that could mean they are incorporated into new electronic designs. As a result, it is still possible to buy these resistors new.

It is necessary to remember that these resistors are bulky, they have a tendency to vary in value and they generate considerable amounts of noise. The exhibit a considerable variation in resistance over time, and when over-voltages are applied. This means that older carbon composition resistors should be treated with caution when re-using them or when repairing vintage radio or other equipment.

Carbon film: Carbon film resistors followed on from the carbon composition resistors. They were very much smaller and more stable. Although the noise level was not as high as that of carbon composition resistors, it was still higher than that of more modern resistors like the metal film resistor. It is still possible to buy carbon film resistors from most stockists and electronic component distributors.

Metal oxide film : Metal oxide film resistors axial leaded resistors are made from a thin film of metal oxide that has been deposited into a ceramic rod. The resistor was considered as the successor to the carbon film resistor as its performance was superior but as the metal film resistor was introduced, with a superior level of performance to that of the metal oxide film resistor, its use declined., although it is still used in some areas because some areas of its properties and specification exceed that of the metal film resistor.

Metal film: Metal film resistors are the standard leaded format that is used these days. These resistors are available with a wide variety of specifications including the resistance values and wattages. They are low noise and can be obtained to 1% or 2% as standard. Closer tolerance varieties are available. They are available in all the standard ranges: E3, E6, . . . . E192.

These resistors are widely available as leaded components, and the same technology is used in surface mount devices as well.

- Surface mount resistors: Surface mount resistors are used in vast quantities for volume manufacture - they are manufactured in terms of billions each year. As mentioned above, metal film resistor technology is generally used as it lends itself to high volume manufacture of surface mount resistors.

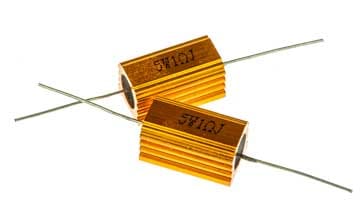

Diagram of a typical SMD resistor Wire wound resistors : Wire wound resistors are typically used where higher power limits are required. Specific power resistor types are available that can be bolted to a chassis or heat sink to remove the heat. Sometimes they may also be used for very close tolerance applications in measuring instruments as they can be very closely trimmed to provide the required resistance, and they are also very stable.

"Aluminium cased wire wound resistor suitable for bolting to a heatsink

Power dissipation specification

Although the resistance is the key parameter for any type of resistor, another important parameter in the resistor specification is the amount of power it can dissipate.

When current passes through a resistor power is dissipated and this manifests itself in the form of heat. In turn this cases the temperature of the resistor to rise, and if too much current passes through the resistor, the temperature rise can be too great and it can cause the resistance to change, or in extreme cases it can cause damage to the resistor.

The power dissipated in a resistor is easy to calculate. The basic equation for power is:

Where:

W = power in watts

V = voltage in volts

I = current in amps

It is often easier to combine this equation with Ohm's Law to create a more useful equation which calculates the power dissipated from a knowledge of the resistance and the voltage across it:

Where:

R = resistance in ohms.

All resistors have a power dissipation rating specification. This is the maximum power that they are designed to dissipate. The resistor type should be chosen so that this power level is never exceeded in operation. In fact good design practice dictates that the maximum power dissipation should be well inside this.

Many companies involved in electronic circuit design activities operate a practice where they state that the maximum actual dissipation should never exceed around 60% of the rating of the particular type of resistor. By doing this, the reliability of the circuit is improved.

Also where specific power resistors are needed, very careful attention must be paid to the power dissipation and cooling of the resistor to ensure it remains within its ratings.

Power de-rating specification

The resistor specification for power de-rating can be important when components may be expected to run at higher temperatures.

Under these circumstances the resistor will be running hot and it is necessary to ensure that its capability is not exceeded.

Typically the same power dissipation will be quoted up to a given temperature, after which the derating is applied. Typically this is a linear curve above the given temperature.

Temperature coefficient specification

In certain circumstances the resistor specification for temperature coefficient is of importance.

The temperature coefficient specification is the parameter that indicates the change in resistance with changing temperature. The resistor specification for the temperature coefficient will be very dependent upon the type of resistor, and it may also vary from one manufacturer to another.

It is therefore important to check the resistor specification for the temperature coefficient to ensure the particular resistor is suitable for the given application.

The temperature coefficient is the change in value of the resistance over a given temperature change. Normally it is expressed in term of parts per million, ppm, per degree Celcius, i.e. ppm/°C.In other words a 100kΩ resistor with temperature coefficient specification of 1000ppm/°C for a 10 °C temperature rise would change would change by 1000 /1 000000 * 100 * 100 000 Ω = &10Ω. This could be quite significant in some circumstances.

Maximum temperature specification

The resistor specification for temperature needs to be adhered to. Above certain temperatures the resistor may function outside its specified operating parameters. Also under extreme conditions damage could result and the overall circuit may cease to function.

If resistors are operated well above their rated temperatures for extended periods, the value of the resistance can permanently increase, and this could cause the overall circuit to malfunction.

A further reason for operating below the rated temperature is overall reliability. Resistors, and all other components are more likely to fail if operated outside their specified ranges. Often components are operated inside their specification with a good margin to ensure that the reliability is maximised.

Resistor specification for maximum voltage

Resistors are designed to operate up to a certain voltage. Above this voltage there is the possibility of breakdown as a result of the electrical stress applied to the component.

As a result of this resistor data-sheets will contain a resistor specification for the maximum voltage that should be applied.

The actual value will depend on a variety of factors including the physical size of the resistor, its structure, the technology used, and a variety of other factors.

Typically it is not good practice to run a resistor close to its rated voltage specification. Often design standards recommend running a resistor at a maximum of 60% or even les of the maximum rated voltage to ensure reliability is maintained.

Resistor inductance specification

In some instances the inductance presented by a resistor may be important. This is particularly true for RF designs as well as fast digital circuits. Every resistor will present some inductance and this can be important. Even small values of inductance can alter the performance of a circuit as the frequencies rise. They can act as small chokes affecting the RF performance, limiting rise time and the like.

Many leaded resistors have a helical grove cut into the resistive element and this is adjusted to give the required resistance. The fact that the resistive element is in the form of a helix means that there will be added inductance as it will act as a coil. Even if the resistor does not use a helical groove cut, the leads and the resistor structure itself can introduce a very small amount of inductance.

A few resistors will have a specification for the inductance, but for most there is not a defined specification set out in the data-sheet.

For any RF design, surface mount resistors perform well as they are very small, they do not have leads to introduce inductance and many do not have a pattern cut into the resistive element. This can be very important for RF designs and fast digital circuit designs and the like where the top frequencies extend into the microwave region. For very high frequencies, specialised resistors may be required.

Resistor reliability

One of the aims of any electronic circuit design will be to produce a reliable finished product. Each component used will contribute to this and accordingly the resistor reliability specification may be important. Areas where the reliability specification may be needed might include aerospace, medical and military equipment. Domestic products rarely have reliability calculations undertaken during the electronic design process.

The reliability is the statistical probability that a resistor will perform without failure. Often, it is specified as failure rate per 1,000 hours of operation or the mean time between failures, MTBF.

Other points to consider

Although the data sheet parameters are very important, there are also several other aspects to the selection of electronics components, and in this case resistors, for a particular circuit design.

These additional points, look at several points outside the data-sheet. These points can be just as important as the data-sheet parameters in the choice of the right component.

By considering these points, the best resistor can be chosen, not only in terms of the basic parameter specifications, but also in terms of other factors that are equally or even more important.

Key Aspects of Component Selection:

Although it is possible to make many decisions about selecting the right component for a circuit design from the datasheet parameters, this is not the only basis for selecting the right components as there are several other attributes not in the data-sheets that need to be embodied in any decision. These are equally important as the basic specification parameters, but not always taken into account. In our web page, we reveal the key additional aspects to consider so that the overall best choice is made.

Read more about secrets of selecting components.

These resistor specifications are some of the more commonly seen resistor specifications and parameters. Other exist and manufacturer datasheets should be consulted before settling on a given type.

Whether the resistor is to be used for low current areas of an electronic circuit design, whether it is to be used as a power resistor a ballast resistor or whatever, knowing how to interpret and understand the specifications is very important.

More Electronic Components:

Batteries

Capacitors

Connectors

Diodes

FET

Inductors

Memory types

Phototransistor

Quartz crystals

Relays

Resistors

RF connectors

Switches

Surface mount technology

Thyristor

Transformers

Transistor

Unijunction

Valves / Tubes

Return to Components menu . . .