Understanding Connector Specifications & Parameters

When considering the selection of any connectors for electronic equipment, it is necessary to look at the datasheet specifications to discover the performance and other essential details.

Connector Technology Includes:

Connector basics

Connector types

Specifications

Selecting the right connector

D-type connector

IEC power connector

Jack connector

XLR connector

IDC connector

PCB edge connector

DIN 41612 connector

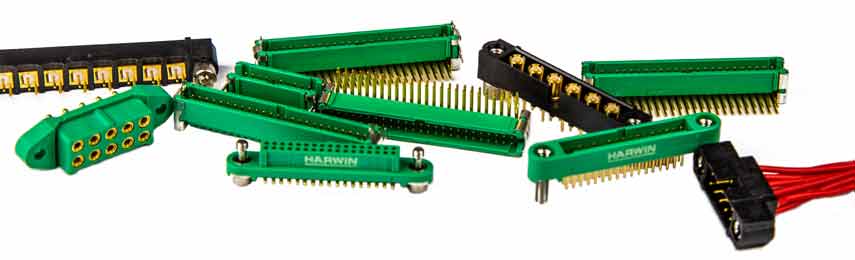

Connectors are an essential type of electronic component found in virtually all electronic designs enabling different assemblies and equipments to be connected and disconnected very easily.

The specifications and parameters seen in connector datasheets provide the important data needed to select the right connector for any given situation or electronic design.

Understanding the different parameters found in the datasheets enables the right choice of connector type and the actual connector to be made for any given situation.

By being able to select the right connector for any given electronic circuit design, it is likely that there could be less issues with the circuit, because connectors can create issues, especially when the wrong type is selected for any given situation.

Basics of connector specifications

As might be expected there is an large amount of terminology associated with connectors and their specifications.

The different connector types as well as the basic formats and the different types of specification.

Aspects from the number of insertions to the contact resistance, current carrying capability, ease of wiring the connector and a host of other parameters are all important when making the selection for the electronic design.

By running the connectors within their specifications and not exceeding them, then the reliability can be expected to be much better and this will obviously be reflected in the overall electronic design or equipment.

Plugs and sockets

One of the basic concepts of connectors is that there are two different formats for connectors. One is the male, or plug, and the other is the mating half that is the socket, receptacle or female section.

The male section has pins, and these are often exposed and therefore plugs are never used to supply power. This would mean that when not connected the accessible pins would be live and there would be a significant risk of them becoming shorted.

Instead the female connector can supply power. The contacts in the female connector are more protected and therefore it is safer to have power on them while there is no mating connection.

Number of pins

When choosing any connector type it is necessary to determine how many pins will be required. This may not only determine the actual connector part, but also the series of connector to be used.

When choosing a particular connector it is standard practice to ensure there are a few spare pins for any future unforeseen requirements in any electronic circuit design. Designing in a little redundancy or space capacity can help if unforeseen connections are required as the design progresses, or if additional capabilities need to be added in a later design upgrade.

However additional pins will add cost and take up space, so a balance between available capacity and additional cost and space needs to be made as the circuit design progresses.

Number of insertions & connector mating cycles specification

All connectors have a finite life and they cannot repeatedly be connected and disconnected endlessly. It is obvious that they will wear each time they are connected and disconnected and this will result in their performance degrading over time as the contact resistance increases.

Often the life of a connector is specified in terms of the number of mating cycles, i.e. a connection and disconnection.

Some connectors that are intended to enable a piece of equipment to be assembled and then are intended only to be disconnected for service and repair may only have a small number of mating cycles.

Others for more general use will have a much larger number. This specification may obviously affect the type of connector chosen for a particular applications.

Although connectors will still operate beyond their stated number of mating cycles, the performance will degrade and could cause problems with the operation of the electronic circuit design.

Mechanical considerations

There are a number of mechanical considerations when choosing connectors. Physical size and shape is an important factor. These mechanical considerations sometimes govern the type of connector that can be used because of the constraints within the electronic design.

Not only can the physical size be an issue, but other aspects including the connection pitch and density may be an issue. The printed circuit board or other wiring method may place constraints on the format of the connector.

These and other mechanical aspects and specifications need to be considered when choosing the type of connector.

RF and screened connectors

Sometimes there are special electrical requirements. One particular case is where the connector requires screening to be contiguous through the connector, or for more exacting requirements where the connector forms part of an RF feeder.

In these cases the connector may need to be coaxial in nature, where the two conductors are manufactured so that one surrounds the other. For RF connectors the requirements may be more exacting because the characteristic impedance of the feeder needs to be maintained through the connector.

Current capability

An important element for any type of connector is its current capability. Some connectors are only designed to carry small currents, whereas others are able to carry much larger levels.

Normally it is only necessary to consider higher current levels, as most connectors can take a few milliamps without a problem. However when looking at low current elves it is necessary to ensure that a good quality connector is used.

Some low cost varieties may form oxide layers that need a certain level of current to flow to enable a good low resistance contact to be made. If currents of a few milliamps or microamps are to be carried, they may not perform well. Often gold plated contacts may be required for the more exacting applications.

It is often found that the current carrying capacity of a pin is not quite adequate. One solution that is often used is to use two contacts instead of one.

The drawback is that the current may not be shared equally between the two contacts and one may exceed its rating. When adopting this approach it is best to leave a large overall margin to ensure that all pins will operate well within their capability.

Voltage capability

There is a maximum operating voltage for connectors. Above a certain voltage it is not safe to operate a connector.

While virtually all connectors will be suitable for low voltages, when they rise to what may be termed hazardous voltages, care needs to be taken as insulation may fail, or there may be flash over.

Accordingly it is always worth ensuring that the maximum voltage is not exceeded and ideally a good margin is present. Specifications may be provided for AC and DC.

Environmental specifications

The environmental specifications for any connector are very important. Although many connectors will be incorporated into electronic designs that will operate in very benign environments, many will need to be able to withstand much harsher environments.

There are several different aspects to the environmental specifications:

Temperature: The temperature specification for a connector is generally the temperature range over which it will operate satisfactorily. The expansion of the materials as well as the additional temperature rises from current being conducted in the contacts may give additional temperature rises which might lead to distortion and failure of the connector.

At the other end of the temperature range, some materials may become brittle at low temperatures and this might cause an issue.

As a result it is necessary to operate the connector within its specified temperature range to ensure the best performance and reliability.

Humidity: Although humidity may not be an issue for many electronic circuit designs, in some instances humidity can be a major issue. Not only can high humidity levels lead to issues with some plastic or insulating materials used for the body of the connector, but it can also lead to a higher possibility of arcing.

Vibration: One major issue associated with all connectors is that they can become disconnected under certain levels of vibration. If electronic designs and electronic equipment in general is subject to high levels of vibration, then specific types of connector need to be used. Checking the vibration specification for a connector can be vital in any application or electronic design where vibration might be expected. Automotive applications are a particular instance.

Insertion force

When connectors mate, there is a certain level of friction between the contacts. This enables good contact to be made, and the contacts to be cleaned.

For many small connectors, this is not a problem. But for many larger connector types with a large number of pins, the force per contact is multiplied by the number of pins used, and this can result in a large amount of force being required to connect and disconnect the connectors. This can be a problem in some instances, and may need to be considered.

For some specialist applications where very large numbers of pins are required, what are termed "Zero Insertion Force" (ZIF) connectors may be used. When mating, the female connector does not allow the male pins to contact the female mating pins, thereby considerably reducing the force. A lever on the side of the female connector brings them into contact once the two halves have mated. This reduces the insertion force to a very small value.

The choice of connector can play an important part in the deign of any equipment. Even when using connectors for home applications it is often useful to have a good understanding of their capabilities and an idea of the key specifications for different types of connector.

More Electronic Components:

Batteries

Capacitors

Connectors

Diodes

FET

Inductors

Memory types

Phototransistor

Quartz crystals

Relays

Resistors

RF connectors

Switches

Surface mount technology

Thyristor

Transformers

Transistor

Unijunction

Valves / Tubes

Return to Components menu . . .